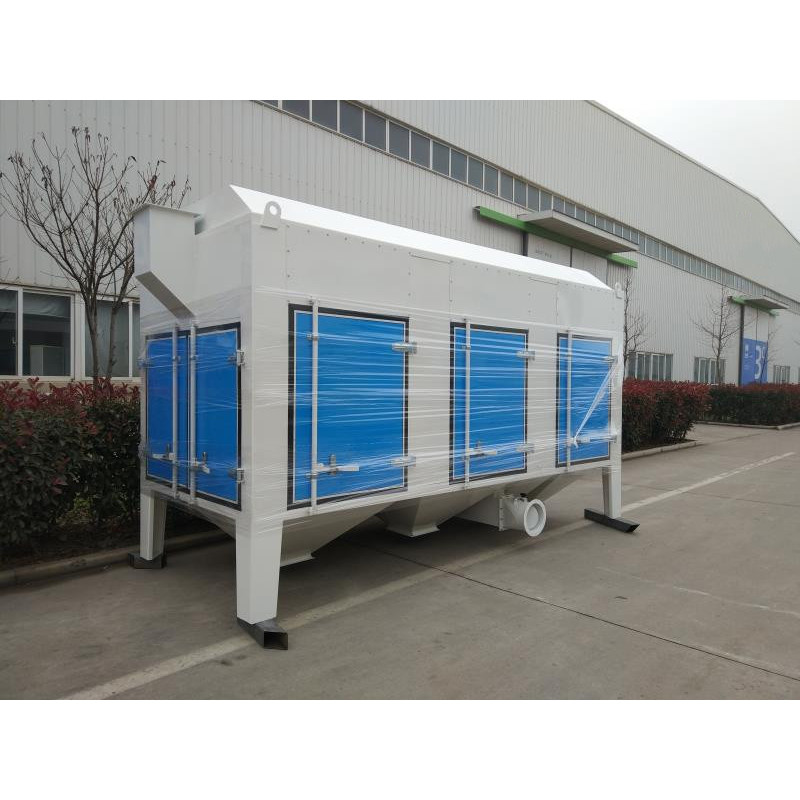

Cylinder Pre cleaning Machine Drum Cleaner Big capacity

Video

Other Information

Loading: Bubble film packaging, bulk, 3 sets in one 40HQ

Productivity: 30t-170t/h

Place of Origin: Hebei

Supply Ability: 100 sets per month

Certificate: CE,SONCAP,ECTN etc.

HS Code: 8437109000

Port: Tianjin,Any Port in China

Payment Type: L/C,T/T

Item: FOB,CIF,CFR,EXW

Delivery Time: 15 Days

Introduction and Function

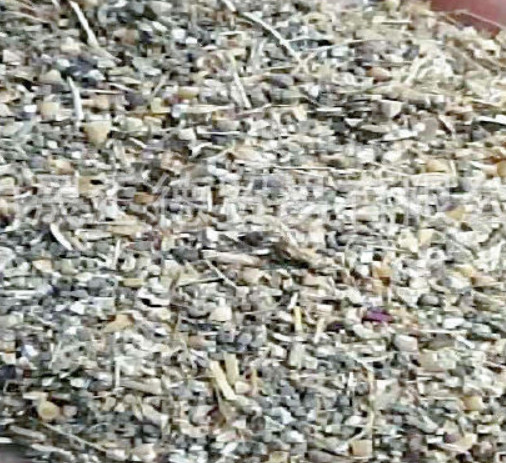

Cylinder Pre cleaning Machine(TFSYT double cylinder series) is suitable for large and small impurities in raw grain, such as wheat straw, hemp rope, bricks, weeds, bean husk, corncob and other impurities and sand, dust, etc. External ventilation network can remove light and dirt from raw grain more effectively.

It is widely used in pre cleaning of raw grain in flour mills, rice mills, oil mills, feed mills, starch mills and grain depots.

This machine is wheat cleaning machine, corn sorting machine.

Specification

| Model Capacity Parameter Grain |

85/190 |

100/220 |

100/320 |

100/420 |

125/320 |

125/420 |

|

| Inner sieve hole diameter (mm) Wheat Outer sieves hole diameter |

Φ22 |

60 |

80 |

110 |

140 |

140 |

170 |

|

Φ20 |

50 |

70 |

100 |

100 |

120 |

150 |

|

|

Φ18 |

40 |

60 |

90 |

90 |

100 |

120 |

|

|

Φ16 |

30 |

50 |

70 |

70 |

90 |

110 |

|

|

mm |

Φ1.8-φ3.2 |

||||||

| Inner sieve hole diameter (mm) Maize Outer sieves hole diameter |

Φ24 |

60 |

85 |

110 |

150 |

150 |

170 |

|

Φ22 |

50 |

75 |

100 |

130 |

120 |

150 |

|

|

Φ20 |

40 |

65 |

90 |

110 |

110 |

130 |

|

|

Φ18 |

30 |

50 |

80 |

100 |

100 |

120 |

|

|

mm |

Φ4.5-Φ6.5 |

||||||

|

1, Sieves is up to the material size 2,It is to clean different material just change different sieves. |

|||||||

Working principle

Cylinder Pre cleaning Machine consists of frame, inclined cylinder, gear, support components. It is mainly used to remove the large impurities and small impurities. When the materials fall into the rotating drum, the materials that smaller than the mesh hole, which will fall to the outlet, and large impurities will rotate in drum and release from the front outlet.

Advantage

1.Big capacity for cleaning larger and smaller impurities.

2.2. Adjustable cylinder angle for flexible process and high efficiency

3.3. Dust cover structure on top/ at stream outlet for hooking up into central cleaning system

4.4. Mobile and Fixed model optional

5. Laser cutting applies to sheet metal components for quality and accuracy