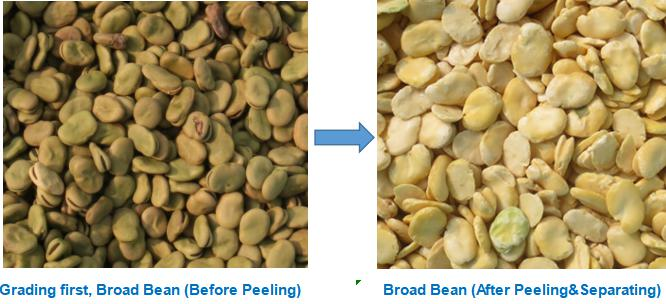

Broadbean Peeling Machine Broadbean Peeler 200-300kg/H

Video

Other Information

Loading: Wooden case

Productivity: 200-300kg/h

Place of Origin: Hebei

Supply Ability: 100 sets per month

Certificate: CE,SONCAP,ECTN etc.

HS Code: 8437109000

Port: Tianjin,Any Port in China

Payment Type: L/C,T/T

Item: FOB,CIF,CFR,EXW

Delivery Time: 7Days

Introduction and Function

Specification

|

Model |

Capacity(KG) |

Power |

Weight |

Overall size |

|

TPJ-CD300 |

200-300 |

4.5KW |

350KG |

1280×1080×1550 |

STRUCTURE

1. The built-in air suction and dust removal system ensures the best sanitary condition. TPJSeries B fine offline is connected with the high-efficiency air suction system. Series A is connected with the air network to ensure the reliability of bran discharge. The cooling system is strong, so as to ensure the high sanitary standard.

2. Simple maintenance, easy operation and quick replacement of sieve plate and other accessories. The durable emery roller has few wearing parts, which make the equipment easy to operate and maintain.

3. The quality of the finished product is uniform and reliable. There are many adjustment options, even in the process of operation - for example, adjusting the feeding speed and the outlet pressure controller to increase the friction and pressure of the peeling chamber, so as to achieve uniform quality and ensure the quality of the finished product.

4. The process of peeling is mild, the flow of beans with high and stable processing efficiency and the efficient air suction system inside the machine make the peeling extremely mild, so as to minimize the grain loss in the process of peeling and ensure the maximum profit.

5. At the same time, the whole dry process is applied to desquamate by dry process, and the product does not contact with water. Compared with wet process, the process is more hygienic.